CASE IH SUGAR CANE HARVESTER AUSTOFT 8000

April 16, 2017

Unknown

4 Comments

April 16, 2017 Unknown 4 Comments

CASE IH HARVESTER

Sugar Cane Harvester Austoft 8000

Case IH is a global reference in the sugar sector and has more than 50 years of knowledge and experience in the sector, which makes it the leader in production and sales of equipment for mechanized sugarcane harvesting.Unique Options

TOTAL PACKAGE

Built with efficiency and longevity in mind, Case IH 8000 Series Austoft®sugarcane harvesters deliver farmers and contractors the total package in cane harvesting:

Built with efficiency and longevity in mind, Case IH 8000 Series Austoft®sugarcane harvesters deliver farmers and contractors the total package in cane harvesting:

- High capacity

- Industry-leading control and adjustment features

- Superior cab comfort for the operator

- Greater harvest efficiency and profitability

- A8000

- Equipped with tires

- Excellent maneuverability

- Faster, 12.4-mph (20-kph) transport speed

- Reduced maintenance costs

- A8800

- Equipped with tracks

- Improved stabilityon sloping terrain

- Agriculturally designed grousers

- Significantly reduce soil compaction.

Engine

- ENGINE FUNCTION GAUGE

- Forward speed

- Engine hours

- Coolant temperature

- Engine load percentage

- Oil pressure

- Any applicable engine error codes.

Every machine is equipped with a digital engine function gauge which replaces previous analog gauges on the cab A-post. Displays major functions:

- THE COOLING PACKAGE

- Remote cooling package with hinged screens

- Reduced maintenance

- Fully reversible hydraulically driven cooling fan

- Ejection of trash removed from the screens (blown from the screen by fan reversal)

- Auto - reversing with operator override.

The 8000 Series Austoft® cane harvester cooling package has been completely redesigned. Updated features include:

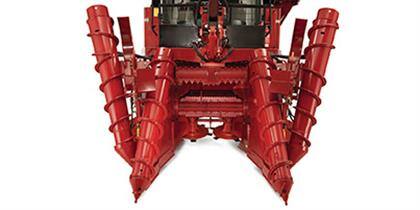

Feeding System

Rain, strong winds, heavy cane varieties and seed can all present unique harvesting challenges. The Case IH feeding system can tackle challenging conditions, even in lodged and tangled cane.

Cleaning

The 8000 Series Austoft® Cane Harvester cleaning system uses the Anti-Vortex System, designed and developed by Case IH. This system is the most modern and efficient cleaning system, it reduces extraneous matter and cane loss and dramatically improves the load density for transport, which lowers operating costs.

Auto Tracker option

The optional Auto Tracker automatic basecutter height system uses sensors and the hydraulic suspension system to automatically raises or lowers itself to improve yield. This easy to use system allows you to concentrate on other harvest functions, is available for all Case IH 8000 Series Austoft® cane harvesters, and can be retrofitted for models manufactured since 1999.

Hydraulic System

SUPERIOR HYDRAULIC SYSTEMS

Case IH Austoft® pioneered the use of hydraulic systems in cane harvesters and has continually simplified and improved efficiency for optimum performance, reduced maintenance, and lower operating costs.

Case IH Austoft® pioneered the use of hydraulic systems in cane harvesters and has continually simplified and improved efficiency for optimum performance, reduced maintenance, and lower operating costs.

Cab

SUPERIOR OPERATOR ENVIRONMENT

The spacious, two-door, walk-through cab on 8000 Series Austoft® sugarcane harvesters offers unrivaled comfort, visibility and control.

The spacious, two-door, walk-through cab on 8000 Series Austoft® sugarcane harvesters offers unrivaled comfort, visibility and control.

Service

EASE-OF-SERVICE

When harvest begins, there is no time to spare. The 8000 Series Austoft® cane harvesters are designed for effortless daily service and simple maintenance.

When harvest begins, there is no time to spare. The 8000 Series Austoft® cane harvesters are designed for effortless daily service and simple maintenance.

Agriculture equipments se very important to understand before you start farming or home gardening

ReplyDeletepeople have to know about each and every tools of agriculture to take better results in farming and to be safe during farming.

thanks for writing and sharing this article with us!!

keep up!!

best wishes!!!!

I have found this article very interesting

ReplyDeleteIf you want to purchase tractor then do visit our website

Visit here: TractorGuru

Amazing article.

ReplyDeleteThank you for sharing with us.

Kubota Tractor

I would really like to appreciate your work.

ReplyDeleteThanks for sharing this post.

TractorGuru